Vision Sorting for Bakeries

A flexible and intuitive solution for order distribution in wholesale bakeries.

Sorting in bakeries

Fast and accurate sorting and delivery. Every wholesale bakery performs this, sometimes multiple times every day.

Large wholesale bakeries often use LED displays for a paperless dispatch order system. Such “Put-to-Light” systems offer a good performance and high quality for the distribution of bakery products in very large bakeries. Such installations require a high up-front investment and a fixed hardware installation.

Vision sorting

Without the need for investing in screens, cabling, converters and other site-wide hardware, ART4L’s Vision Sorting offers similar performance and higher flexibility than classic approaches, simply by providing operators with a Smartglass and marking drop locations with printable visual tags.

Key Benefits

- work hands-free, no more paper lists

- improve efficiency with over 20%

- reduce errors up to 60%

- reduce operator work stress

- easy installation, no site-wide wiring or screens

- scales efficiently with increasing production loads

- up and running within weeks

- Return on investment of less than 12 months

Work hands-free

In most bakeries customer’s distribution points are distinct locations in the warehouse, typically aligned side by side. An operator will take a product and walk past each location and drop the product where needed, cross checking the desired amounts with a list on paper. This is a labor intensive, stressful and error-prone approach.

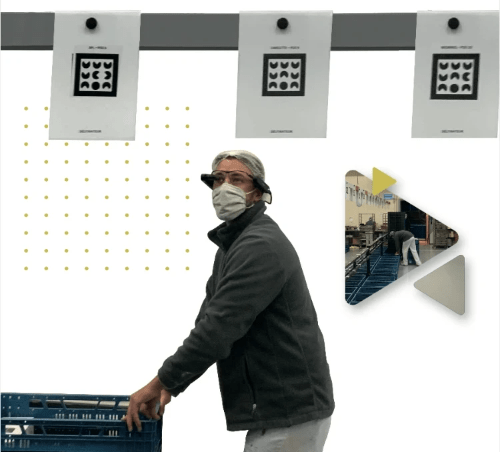

With ARTL4’s Put-By-Vision system, an operator is wearing a Smartglass, allowing the user to see the real world, enriched with computer generated data and images. This Smartglass works in combination with unique location markers, printed on paper, that is attached at each distribution point.

How It Works

Vision sorting step-by-step

1Scan

Scan a product and walk to the first drop location

2Glance

The Smartglass shows the correct drop amount at the location on the visual marker

3Drop

Drop the right amount of product at the location

4Prepare

Look ahead to the next drop location where the correct drop amount is already visible

Vision sorting in action

See through the eyes of a user of the Vision sorting solution

Interested to take your sorting to the next level?

© 2025 ART4L NV - Belgium